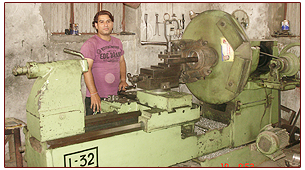

Our Infrastructural Facilities

The company has modernized its plant with “NKH” self contained friction drop forging hammer being manufactured in eight different capacities 500 KGS. , 750 KGS. , 1000 KGS. , 1500 KGS. , 2000 KGS. , 2500 KGS. , 3000 KGS. , & 4000 KGS capacity. Verification activities are carried out at goods inward stages, in-process stages and final inspection stages. The verification points and parameters are identified and verification is carried out as per laid down procedures. Text plans and work instructions are applicable. The requirements of in-house inspection, measuring, testing and monitoring equipment’s and personnel are identified from time to time. Whenever the company introduces a new product or affects a change in the manufacturing process, production in-charge assesses the new requirements in collaboration with different shop in-charge for inspection, measuring, testing, monitoring equipment’s and personal.